how to calibrate a rockwell hardness tester|rockwell hardness testing chart : service This video shows how to adjust a Rockwell Hardness tester. O Bitcoin está revolucionando o mundo financeiro. No entant.

{plog:ftitle_list}

WEBGato do Sol

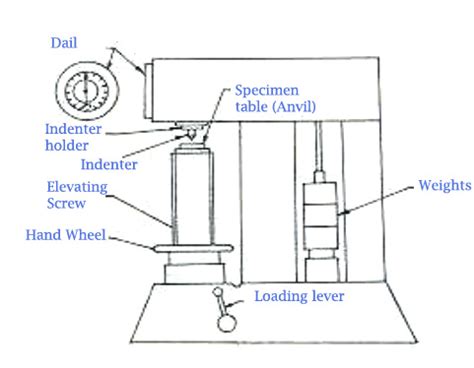

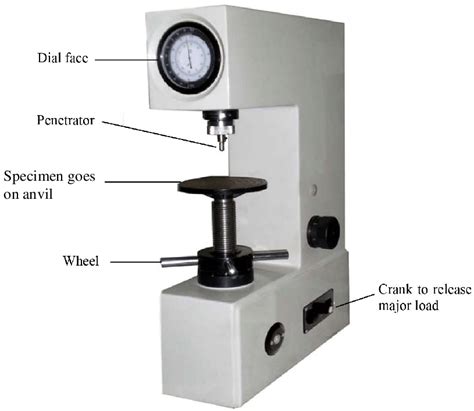

rockwell hardness testing machine diagram

In this video Corin demonstrates how to set up and calibrate your hardness tester, if you're interested in one of these units join our bulk buy page on Faceb. For calibration, you need several test blocks to cover the range you test. An improperly adjusted tester can be correct at one hardness, and off at higher and/or lower .How to Calibrate a Rockwell Hardness Tester. Calibrating a Rockwell hardness tester is essential to establish a reference point for accurate hardness measurements. Over time, factors such as wear and tear, .Description. The Starrett 3814 accurately measures hardness of materials in Rockwell hardness A, B, and C scales. Heat-treated steels are tested using a 120 diamond indenter in the C-scale .

This video shows how to adjust a Rockwell Hardness tester. Calibration of hardness testers was covered during Hardness Days. Here you can see Buehler's Senior Service Technician Mike Conner, discuss daily, indirect a.The 3831Digital Rockwell Hardness Tester can be used directly to measure the most popular regular Rockwell hardness scales and it can quickly convert that hardness value into HB, HV, .

TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 .this tester uses the standard test method for rockwell and Superficial rockwell hardness testing per AStM e-18. 2.1.1 Basic Operation 1. turn power switch on (back of the tester). the .The Rockwell test is based on measurement of the depth of penetration with the hardness number read directly from the dial gauge or digital display that is part of every tester. In . The diamond indenter shall be free from surface defects (cracks, chips, pits, etc.) and polished to such an extent that no unpolished part of its surface makes contact with the test piece when the indenter penetrates to a depth of 0.3 mm for Rockwell hardness testing and 0.2 mm for Rockwell superficial hardness testing.

How to use the Rockwell hardness test for quick hardness testing in the lab or production environment. Vickers Hardness testing (HV) . Hardness Tester Calibration & Certification Requirements Know the requirements of calibration of various hardness testers and successfully pass your next audit.II. Theory and Principle of the Rockwell Hardness Test. The Rockwell Hardness Test uses a depth-differential method to test for hardness. A predetermined minor load is applied to the test sample, and the depth measurement is taken. Then a major load is applied to the same spot, which creates a deeper indentation.We offer calibration of the following Hardness Testers: Standard Rockwell Hardness Testers which include C, B, and A Scales. To certify your Standard Rockwell Hardness tester to the current revision of ASTM E18, you are required to have certified penetrators. If certified penetrators are not available, we can certify your tester to the previous .

profiles. The Rockwell test is the most popular indentation hardness test and is used in a wide variety of applications. Advantages of the Rockwell Test There are several reasons for the popularity of the Rockwell test. The test itself is very rapid. On a manually operated unit, a Rockwell test takes only five to ten seconds, Calibrating the Rockwell hardness tester.

This video shows how to adjust a Rockwell Hardness tester.

this tester uses the standard test method for rockwell and Superficial rockwell hardness testing per AStM e-18. 2.1.1 Basic Operation 1. turn power switch on (back of the tester). the display will read SeLF teSt 2. After a few seconds the display will change to show the scale and status, for example: HrC Set 3.

The Rockwell hardness test is less affected by surface rough-ness compared to other methods such as the Vickers or Brinell tests. It can provide reliable hardness measurements even on surfaces with moderate roughness, making it a practical choice for a wide range of materials and surface conditions.

Verification should be performed by an accredited verifying agency and the report should follow and reference ASTM E18 Rockwell test method. Hardness testing is an important and useful tool in materials testing, quality control and acceptance, and performance of materials. . Rockwell Hardness Testing Calibration Kits;The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test. The Rockwell test is generally easier to perform, and more accurate than other types of hardness testing methods .In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested. Starrett Hardness Testers indicate the hardness of a material, usually by measuring the effect on its surface of a localized penetration by a standardized rounded or pointed indenter of diamond, carbide, or hard steel. . With a range of models available, including Rockwell, Brinell, and Vickers testers, Starrett offers the perfect tool for .

Newage Testing Instruments offers calibration and verification services for all of your hardness testing instrumentation per industry standards such as ASTM E18 and ISO 6508-2. Our field service technicians are factory-trained and accredited to provide you with accurate and economical calibration support.

rockwell hardness testing chart

mechanical performance test fails. Rockwell hardness tester Model HR-150A won the silver medal of the State Superior Product for three consecutive sessions. It is widely used to measure the Rockwell hardness of hard alloy, quenched and unquenched steels in the labs of research institutions, colleges, factories and mines. 2. Principle of TestRockwell hardness test: Rockwell hardness test with the method of measuring pressure depth, hardness value through instructions direct reading, therefore, simple and convenient operation, easy to grasp, high efficiency, suitable for batch parts inspection; Rockwell hardness test method, can use diamond indenter and

Alvin, Our rockwell over the years (10+) had given us so much trouble from oems during audits- we finally took it out of our documentation and processes. It was the first area they always went to to look for issues even though it isn't a requirement (for us) in any specification. We used internally for a hardness check.Hardness Calibration. . E-18 Standard Test Method for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Material; E-92 Standard Test Method for Vickers Hardness of Metallic Material 1kgf to 120kgf; E-103 Rapid Indentation Hardness Testing of Metallic Material;Model No. PHT-1900 Features. State of the art, digital portable hardness tester is designed to test the hardness of large hard metal parts. Clean crisp display shows the incredible functions that can only be found on this new portable hardness tester such as auto-probe detection, auto direction detector, single and multi-point calibration make the new 1900 the most versatile .Calibration of Hardness Tester Learn how to verify the performance of Hardness Tester used to check the hardness of tablets. Ankur Choudhary 2024-04-17T15:59:53Z Print Online Courses Question Forum 2 comments

ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application. Starrett Hardness Testers indicate the hardness of a material, usually by measuring the effect on its surface of a localized penetration by a standardized rounded or pointed indenter of diamond, carbide, or hard steel. . With a range of models available, including Rockwell, Brinell, and Vickers testers, Starrett offers the perfect tool for .The Rockwell hardness test is less affected by surface rough-ness compared to other methods such as the Vickers or Brinell tests. It can provide reliable hardness measurements even on surfaces with moderate roughness, making it a practical choice for a wide range of materials and surface conditions.

The Wilson Rockwell 574 Hardness Tester Series stands out for its quality, durability, and leading Gauge Repeatability and Reproducibility (GR&R) in hardness testing instruments. Skip to content +1 847-295-6500; [email protected]; . Rockwell Hardness Testing Calibration Kits; Portable hardness tester at a great price. All features of much more expensive testers. . This is a short video on how to calibrate a THX281 portable hardness tester. Also shows how to change the language. View more. . THX210 Portable Hardness Tester Rockwell Brinell Vickers CIMETRIX. ,100.00 9.00. Add to Cart. Compare at 00.For companies looking for a portable hardness tester standard E-110 to portable Rockwell hardness testers. The general testing procedure of E-110 is as follows: A rounded penetrator of known hardness is forced into the test surface under a specific pressure load.

Thanks for watching, Please COMMENT, LIKE & SUBSCRIBE.. All music written, played and produced by Dave Erving.2nd Channel(music) -https://www.youtube.com/ch.

Fixed Online Gas Detector suppliers

6 de dez. de 2023 · Club Aurora x Vaca Diez: Estatísticas e Análise Pré-Jogo - LFPB 2023. Aqui na APWin você encontra todas as estatísticas para Club Aurora x Vaca Diez, jogo que será disputado no dia 06/12/2023, às 00h00. Nesta página, você tem uma análise completa com estatísticas importantes sobre o desempenho de ambas as equipes ao .

how to calibrate a rockwell hardness tester|rockwell hardness testing chart